We can provide customized products and project products according to specific requirements. Please feel free to contact us if you need.

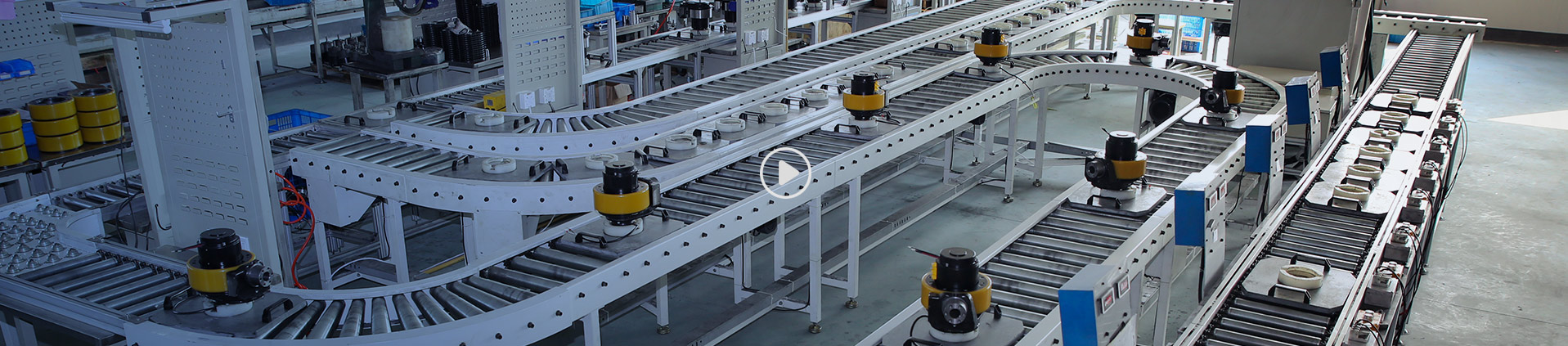

This type of motor roller can be installed in limited space and meet the torque requirement.Using alloy steel grinded gears and planetary transmission structure,it is reliable,free of maintenance and oil-renewing,space-saving.It can be use in many fields:

●Supermarket cashier

●Packaging machinery

●Belt conveyor line

●Roller Shell

•Material of standard roller shell is mild steel

•Food garde shell is 304 stainless steel

●Gear Drive

•High alloy steel precision

•Planetary gear transmission

●Gearbox

•Ensure the transmission with low noise,using the new polymer planetary gear and metal gear transmission

●Motor

•When 50Hz or 60Hz is used,it can be applied to all kinds of universal voltage

•Motor insulation class F

•AlI motor with thermal protection

•Loose wire,outlet length 0.5M

●Seal Level

•Shaft end use of skeleton oil seal

•Motor roller sealing protection level is IP40/IP54

●Oiling

•Before leaving factory,all products is filled will oil in standard amount,so no need of maintenance or oil-renew

●Other

•Able to be installed in multiple direction

•Able to work with electromagnectic brake,but the length will be longer

•Single-phase motor can work with speed control

•All customized requirement can be considered

|

PN |

np |

gs |

i |

V |

nA |

MA |

FN |

SLmin |

|

0.035 |

2 |

1 |

3.6500 |

129.107 |

684.9 |

0.40 |

14 |

350 |

|

5.3600 |

87.918 |

466.4 |

0.60 |

21 |

350 |

|||

|

6.5500 |

71.945 |

381.7 |

0.80 |

25 |

350 |

|||

|

8.6300 |

54.605 |

289.7 |

1.00 |

33 |

350 |

|||

|

2 |

13.530 |

34.829 |

184.8 |

1.40 |

47 |

350 |

||

|

18.920 |

24.907 |

132.1 |

2.00 |

66 |

350 |

|||

|

24.650 |

19.117 |

101.4 |

2.60 |

86 |

350 |

|||

|

28.050 |

16.800 |

89.10 |

2.90 |

97 |

350 |

|||

|

33.920 |

13.893 |

73.70 |

3.50 |

118 |

350 |

|||

|

44.690 |

10.545 |

55.90 |

4.70 |

155 |

350 |

|||

|

58.220 |

8.094 |

42.90 |

6.10 |

202 |

350 |

|||

|

3 |

67.080 |

7.025 |

37.30 |

6.30 |

210 |

350 |

||

|

81.110 |

5.810 |

30.80 |

7.60 |

254 |

350 |

|||

|

91.360 |

5.158 |

27.40 |

8.60 |

286 |

350 |

|||

|

102.88 |

4.580 |

24.30 |

9.70 |

322 |

350 |

|||

|

118.98 |

3.961 |

21.00 |

11.2 |

372 |

350 |

|||

|

127.74 |

3.689 |

19.60 |

12.0 |

400 |

350 |

|||

|

145.36 |

3.242 |

17.20 |

13.6 |

455 |

350 |

|||

|

191.56 |

2.460 |

13.10 |

18.0 |

599 |

350 |

|||

|

231.61 |

2.035 |

10.80 |

21.7 |

725 |

350 |

|

PN |

np |

gs |

i |

V |

nA |

MA |

FN |

SLmin |

|

0.040 |

2 |

1 |

3.6500 |

129.107 |

684.9 |

0.50 |

16 |

350 |

|

5.3600 |

87.918 |

466.4 |

0.70 |

24 |

350 |

|||

|

6.5500 |

71.945 |

381.7 |

0.90 |

29 |

350 |

|||

|

8.6300 |

54.605 |

289.7 |

1.10 |

38 |

350 |

|||

|

2 |

13.530 |

34.829 |

184.8 |

1.60 |

54 |

350 |

||

|

18.920 |

24.907 |

132.1 |

2.30 |

75 |

350 |

|||

|

24.650 |

19.117 |

101.4 |

2.90 |

98 |

350 |

|||

|

28.050 |

16.800 |

89.10 |

3.30 |

111 |

350 |

|||

|

33.920 |

13.893 |

73.70 |

4.00 |

135 |

350 |

|||

|

44.690 |

10.545 |

55.90 |

5.30 |

177 |

350 |

|||

|

58.220 |

8.094 |

42.90 |

6.90 |

231 |

350 |

|||

|

3 |

67.080 |

7.025 |

37.30 |

7.20 |

240 |

350 |

||

|

81.110 |

5.810 |

30.80 |

8.70 |

290 |

350 |

|||

|

91.360 |

5.158 |

27.40 |

9.80 |

327 |

350 |

|||

|

102.88 |

4.580 |

24.30 |

11.0 |

368 |

350 |

|||

|

118.98 |

3.961 |

21.00 |

12.8 |

425 |

350 |

|||

|

127.74 |

3.689 |

19.60 |

13.7 |

457 |

350 |

|||

|

145.36 |

3.242 |

17.20 |

15.6 |

520 |

350 |

|||

|

191.56 |

2.460 |

13.10 |

20.5 |

685 |

350 |

|||

|

231.61 |

2.035 |

10.80 |

24.8 |

828 |

350 |

| PN: Rated power | np:Series | gs:Gear series |

| i:Reduction ratio of | v:Outside the rated speed | nA:Outer tube rated speed |

| MA:Motor roller rated torque | FN:Traction force | SLmin:The shortest outer tube length |

|

Component Description |

Motor roller |

|

Roller shell |

|

|

Carton steel straight dmm |

1 |

|

Stainless steel (standard 304) straight drum |

2 |

|

Front end cover |

|

|

Cast aluminum cover |

1 |

|

Nickel plated aluminum cover |

2 |

|

Stainless steel (standard 304) end cover |

2 |

|

Front and rare shaft |

|

|

Carbon steel shaft |

1 |

|

Stainless steel shaft |

2 |

|

Motor |

|

|

Single phase or three phase asynchronous motor |

1 |

|

Voltage 1 *220V/50Hz or 3*380V/50Hz |

1 |

|

Global common voltage under 50Hz or 60Hz conditions |

1 |

|

Thermal protector |

1 |

|

Oil for room temperature |

2 |

|

Electrical connection |

|

|

Straight connector |

1 |

|

Other options |

|

|

Eletromagnectic brake |

2 |

|

Can be installed in different directions |

1 |

|

Connected converter |

2 |

|

Single phase can work with speed controller |

2 |

|

Double flat shaft |

1 |

|

D shape shaft |

2 |

|

Six angle type shaft out shaft |

2 |

|

Note:

|

||

| 1-Standard option | 2-Non-standard option | 3-Restrained option,contact manufacturer if needed |

Ningbo Zhongda Leader Intelligent Transmission Co., Ltd is a High-tech public enterprise specializing in research & development, manufacture, sales and service of motor driver, micro motor and high precision gearbox. August 29, 2017, Zhongda went public in the Shenzhen Stock Exchange SME board A-shares (stock code 002896), As a one of the powerful DM60 AC Motor Roller manufacturers and DM60 AC Motor Roller suppliers in China. our company Participated in the drafting of 7 National Industrial Standards, Own 90 national patents, Have Zhejiang provincial enterprise R & D Center, our DM60 AC Motor Roller and other products are widely used in industrial robots, intelligent logistics, new energy, machine tools and other fields, as well as special machinery and equipment for food, packaging, textile, electronics, medical, etc. for their differentiated and cost-effective advantages.

No. of Employees: 1,500 employees

Mission: Zhongda realizes the infinite possibilities in automation applications.

Main Business: It is a High-tech public enterprise specializing in research & development, manufacture, sales and service of motor driver, micro motor and high precision gearbox.

Main Products: Micro DC & AC gear motor, small AC gear motor, planetary gearbox, high precision cycloidal gearbox and motor driver, etc.

Tips: Not all gearbox catalogue listed. Feel free to inquire and get latest catalogue. Need solution? We'd like to help.

Show Information

News & Media

Industry News

What are the advantages of planetary gear motors in the field of robotics?

1. Efficient and compact design, breaking through space limitationsThe planetary gear motor adopts a unique planetary gear train structure (sun gear, ......

Industry News

Why are planetary gearboxes widely used in high-precision equipment?

I. Technical Features: Core Engineering ExcellenceUltra-Low Backlash & High Positioning AccuracyPlanetary gearboxes utilize precision meshing desi......

Industry News

How to Determine if a Gear Motor Needs Replacement?

1. Mechanical Wear and Structural IntegrityThe first step is to inspect the mechanical components for irreversible wear or damage. Gears should be exa......

Industry News

What are the advantages of using gear motors in the field of automation?

1. High torque output and power adaptabilityGear motors convert the high-speed and low-torque output of motors into low-speed and high-torque through ......

Industry News

What are the Applications of AC Gear Motor in the Commercial Ice-making Equipment?

Commercial ice-making equipment is a machine used for large-scale production of ice cubes or ice particles, widely used in the catering, medical, and ......

Industry News

What Are the Gears Used in a Planetary Gearbox?

1. Sun GearLocated at the center of the assembly, the sun gear is driven by the input shaft and transmits rotational force to the planetary gears .Typ......