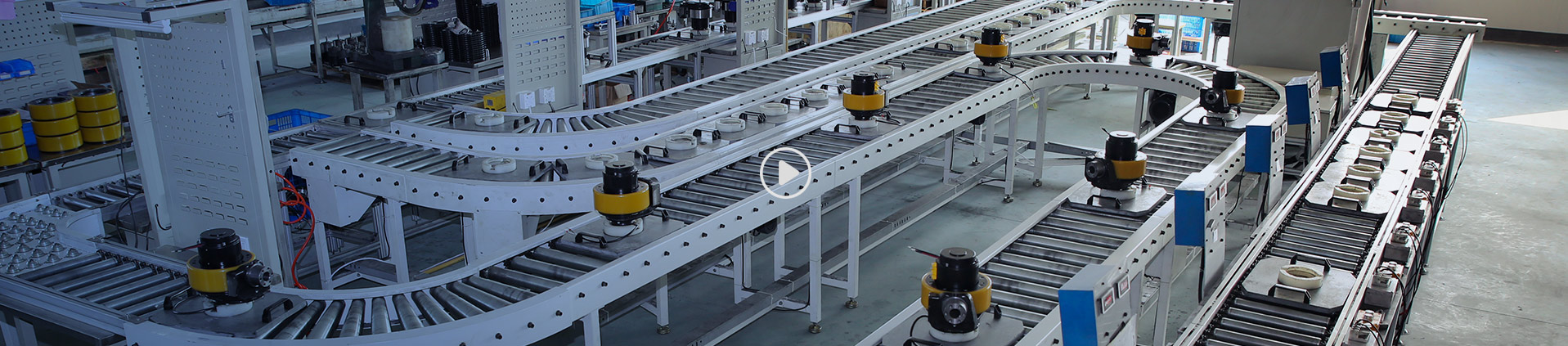

●Motor roller is a new type of drive device which is placed in the roller body together with the motor and the gearbox. It is mainly used in fixed and movable type belt conveyor, to replace traditional type, which motor, gearbox are separated with roller.

●Motor roller can run under severe particulates environment; can withstand the flow of water and spray, can resist most of the erosion environment. Due to the protection level IP66 and stainless steel material (as required), motor roller also applied to food processing, pharmaceutical and other industries.

●Motor roller driven by AC asynchronous induction motor, suitable for most of the international common voltage, also can be customized according to customer requirements.

●The motor roller contains oil as a lubricant and coolant, heat dissipation through the roller shell and the transfer of heat. When using an motor roller without a conveyor belt, a special design can be carried out to ensure that the cooling.

●Integrated thermal protection: integrated constant temperature protection switch in the motor winding end. When the motor is over heat, the switch is switched on. However, the switch must be connected to a suitable external controller, the controller can interrupt the current conveyor to the motor in case of overheating.

●Integrated electromagnetic brakes: the integrated electromagnetic brake can delay and stop the weight of the given conveyor belt. It will directly affect the axis of the motor roller, driven by DC electric rectifier.

●Mechanical anti reversing device: a mechanical anti reversing device mounted on a rotating shaft can be used to increase the conveyer. In the case of current interruption, it can inhibit the transfer of the backward running.

●Rotary encoder: the pulse can be used to position and control the speed and direction of rotation.

|

Protection Level

|

IP66

|

|

Ambient temperature range for general application

|

+5°C~+40°C

|

|

Environmental temperature range of low temperature application

|

-25°C~+15°C

|

|

Cycle time

|

Start / stop at most 3 times per minute

Using frequency converter or the use of special structure, the time may be higher

|

|

Mounting height

|

Maximum elevation 1000m

|

According to the different environmental temperature, different types of lubricating oil must be used. When the ambient temperature is lower than +5°C, it is recommended to use static heating. When the temperature is lower than -20°C, must use special seal and cable.

Under normal operating conditions, the stator winding in the integrated thermoelectric circuit breaker has been closed, When the motor reaches the edge temperature (over temperature), the switch is opened at a predetermined temperature (depending on the insulation level of the winding), which is used to prevent damage to the motor.

|

Warning

|

|

When the motor cooling, the thermal power circuit breaker will automatically reset.

• Thermoelectric breakers must be converted to a series of current contacts for a relay or a series of electric current.

• After the switch is triggered, wait until the motor cools down. To ensure the safety of personnel and equipment before the connection.

|

●Motor rated voltage: 220/380V - 3 phase - 50Hz

●Line voltage: 220/380V- 3 phase - 60Hz

If a 50Hz motor is connected to the 60Hz line, the frequency will be increased and the speed of the motor is increased by 20%. In order to keep the motor constant, the input voltage should be increased by 20%. If no input is increased by 20%, the parameters will be changed according to the following table:

| Line Voltage = Motor Rated Voltage |

|

Power

|

P

|

kW

|

100%

|

|

Rated speed

|

nn

|

U/min

|

120%

|

|

Rated torque

|

Mn

|

Nm

|

83.3%

|

|

Starting torque

|

MA

|

Nm

|

64%

|

|

Traction torque

|

MS

|

Nm

|

64%

|

|

Stop torque

|

MK

|

Nm

|

64%

|

|

Rated current

|

IN

|

A

|

95%

|

|

Peak current

|

IA

|

A

|

80%

|

|

Power factor

|

cosФ

|

-

|

106%

|

|

Efficiency

|

η

|

-

|

99.5%

|

●Motor rated voltage: 220/380V - 3 phase - 50Hz

●Line voltage: 264/456V - 3 phase - 60Hz - 2&4 (motor voltage + 20%)

If the voltage is increased by 20% in a 60Hz line running 50Hz motor, the frequency will be increased and the speed of the 20% is increased. Motor ratings are only small deviations. If the input voltage is 15% to the motor voltage, the actual motor power will be reduced to 92% of the original motor power.

|

Line Voltage = 1.2 x Motor Rated Voltage (Applicable To 2 And 4)

|

|

Power

|

P

|

kW

|

100%

|

|

Rated speed

|

nn

|

U/min

|

120%

|

|

Rated torque

|

Mn

|

Nm

|

100%

|

|

Starting torque

|

MA

|

Nm

|

100%

|

|

Traction torque

|

MS

|

Nm

|

100%

|

|

Stop torque

|

MK

|

Nm

|

100%

|

|

Rated current

|

IN

|

A

|

120%

|

|

Peak cuuent

|

IA

|

A

|

100%

|

|

Power factor

|

cosФ

|

-

|

100%

|

|

Efficiency

|

η

|

-

|

98%

|

EN

EN