We can provide customized products and project products according to specific requirements. Please feel free to contact us if you need.

●25W (DC Power Supply When Applied To 24VDC/36VDC/48VDC)

|

Rated power (Continuous) |

W |

25 (15W/25W) |

|||

|

Rated speed |

r/min |

2500 |

|||

|

Rated torque |

N.m |

0.096 |

|||

|

Instantaneous maximum torque |

N.m |

0.144 |

|||

|

Rotor moment of inertia |

J:X10-4kg.m2 |

0.042 |

|||

|

Speed control range |

RPM |

High pressure 200-2500RPM (Low pressure 200-3000RPM) |

|||

|

Speed control range |

On load |

Below ±1%: condition 0~rated torque, rated speed, rated voltage, room temperature |

|||

|

On voltage |

Below ±1%: condition rated voltage ±10%, rated speed, rated load, room temperature |

||||

|

On temperature |

Below±1%: Conditions of ambient temperature 0~+40°C rated voltage, ratod load and rated speed |

||||

|

Power input |

Rated voltage |

V |

Single phase 110V |

Single phase 220V |

24VDC (Optional 36VDC/48VDC)

|

|

Voltage tolerance range |

±10% |

||||

|

Frequency |

Hz |

50/60 |

/ |

||

|

Frequency tolerance range |

±5% |

/ |

|||

|

Rated input current |

A |

1.0 |

0.6 |

1.7 |

|

|

Instantaneous maximum input current |

A |

2.0 |

1.2 |

2.6 |

|

● Z2BLD25-◘A-25S ━Voltage 24/36/48/110/220

|

● Z2BLD25-220A-25S Diagram

|

● Low Voltage Wrie Plughole Corresp-onding Signal Explanation |

● High Voltage Wrie Plughole Corresp-onding Signal Explanation |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

● Parallel Shaft Speed Reducer Z2BLD25-◘GN-25S/2GNDK ◘ —Voltage 24/36/48/110/220

①Connector:5557-8R/10R(MOLEX) ②The sheath length of lead line 300mm ③Round terminal:SRA-21T-4(Low ground) |

● Decimal Gearhead 2GN□XK □—Velocity Ratio Value, Generally 10

•Enter the gear ratio in the box (□) within the model name |

•Z2BLD15-◘GN-25S/2GN□K Machine Allowable Torque (Unit: N.m)

|

Model |

Motor Speed/Reduction Ratio |

3 |

3.6 |

5 |

6 |

7.5 |

9 |

10 |

12.5 |

15 |

18 |

20 |

25 |

30 |

36 |

50 |

60 |

75 |

90 |

100 |

120 |

150 |

180 |

200 |

|

Z2BLD15-□GN |

200~1500RPM |

0.18 |

0.22 |

0.30 |

0.36 |

0.45 |

0.54 |

0.60 |

0.75 |

0.91 |

1.08 |

1.09 |

1.36 |

1.63 |

1.96 |

2.72 |

2.95 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

|

2000RPM |

0.17 |

0.21 |

0.29 |

0.35 |

0.44 |

0.52 |

0.58 |

0.73 |

0.87 |

1.04 |

1.30 |

1.56 |

1.87 |

2.60 |

2.82 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

|

|

2500RPM |

0.14 |

0.17 |

0.23 |

0.28 |

0.35 |

0.42 |

0.46 |

0.58 |

0.70 |

0.84 |

0.84 |

1.05 |

1.25 |

1.51 |

2.09 |

2.27 |

2.83 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

•Z2BLD25-◘GN-25S/2GN□K Machine Allowable Torque (Unit: N.m)

|

Model |

Motor Speed/Reduction Ratio |

3 |

3.6 |

5 |

6 |

7.5 |

9 |

10 |

12.5 |

15 |

18 |

20 |

25 |

30 |

36 |

50 |

60 |

75 |

90 |

100 |

120 |

150 |

180 |

200 |

|

Z2BLD25-□GN |

200~1500RPM |

0.30 |

0.36 |

0.50 |

0.60 |

0.75 |

0.91 |

1.00 |

1.26 |

1.51 |

1.81 |

1.81 |

2.27 |

2.72 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

|

2000RPM |

0.29 |

0.35 |

0.49 |

0.58 |

0.73 |

0.87 |

0.97 |

1.21 |

1.46 |

1.75 |

1.75 |

2.18 |

2.61 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

|

|

2500RPM |

0.23 |

0.28 |

0.39 |

0.46 |

0.58 |

0.69 |

0.77 |

0.97 |

1.16 |

1.39 |

1.39 |

1.74 |

2.09 |

2.51 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

Note :The■ (gray) in the table indicates that the rotation direction is consistent with the motor.(The torque under different speed and speed ratio is obtained under the ZD standard.)

•L Type Speed Reducer

•Z2BLD15-◘GNL-25S/2GN□LC Machine Allowable Torque (Unit: N.m)

|

Motor Speed/Reduction Ratio |

5 |

10 |

15 |

20 |

30 |

50 |

100 |

200 |

|

200-1500RPM |

0.27 |

0.54 |

0.82 |

1.09 |

1.63 |

2.72 |

5.44 |

10.9 |

|

2000RPM |

0.23 |

0.46 |

0.69 |

0.92 |

1.38 |

2.30 |

4.60 |

9.20 |

|

2500RPM |

0.21 |

0.42 |

0.63 |

0.84 |

1.25 |

2.09 |

4.18 |

8.37 |

Note: All gearbox output turn direction in form are opposite as motor turn direction.(The torque under different speed and speed ratio is obtained under the ZD standard.)

•Z2BLD25-◘GNL-25S/2GN□LC Machine Allowable Torque (Unit: N.m)

|

Motor Speed/Reduction Ratio |

5 |

10 |

15 |

20 |

30 |

50 |

100 |

200 |

|

200-1500RPM |

0.50 |

1.00 |

1.51 |

2.01 |

2.72 |

4.53 |

9.06 |

16.4 |

|

2000RPM |

0.43 |

0.85 |

1.28 |

1.70 |

2.30 |

3.83 |

7.67 |

13.9 |

|

2500RPM |

0.35 |

0.70 |

1.05 |

1.39 |

2.09 |

3.49 |

6.97 |

12.6 |

Note: All gearbox output turn direction in form are opposite as motor turn direction.(The torque under different speed and speed ratio is obtained under the ZD standard.)

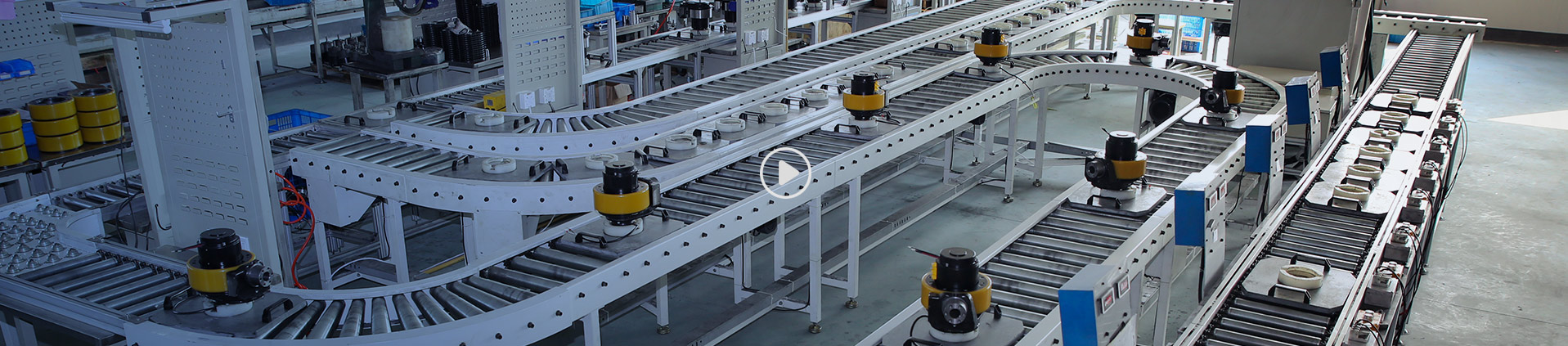

Ningbo Zhongda Leader Intelligent Transmission Co., Ltd is a High-tech public enterprise specializing in research & development, manufacture, sales and service of motor driver, micro motor and high precision gearbox. August 29, 2017, Zhongda went public in the Shenzhen Stock Exchange SME board A-shares (stock code 002896), As a one of the powerful 25W 60 Series Of Brushless DC Gear Motors manufacturers and 25W 60 Series Of Brushless DC Gear Motors suppliers in China. our company Participated in the drafting of 7 National Industrial Standards, Own 90 national patents, Have Zhejiang provincial enterprise R & D Center, our 25W 60 Series Of Brushless DC Gear Motors and other products are widely used in industrial robots, intelligent logistics, new energy, machine tools and other fields, as well as special machinery and equipment for food, packaging, textile, electronics, medical, etc. for their differentiated and cost-effective advantages.

No. of Employees: 1,500 employees

Mission: Zhongda realizes the infinite possibilities in automation applications.

Main Business: It is a High-tech public enterprise specializing in research & development, manufacture, sales and service of motor driver, micro motor and high precision gearbox.

Main Products: Micro DC & AC gear motor, small AC gear motor, planetary gearbox, high precision cycloidal gearbox and motor driver, etc.

Tips: Not all gearbox catalogue listed. Feel free to inquire and get latest catalogue. Need solution? We'd like to help.

Show Information

News & Media

Industry News

What are the Applications of Drive Wheels in Electric Forklifts?

Electric forklifts rely on battery-powered motors for both driving and loading operations. Zhongda offers specialized motors for electric forklifts, s......

Industry News

Why must the robot arm joint use a helical planetary gearbox?

A. The core advantage of helical gear design: from "meshing impact" to "smooth transmission"The instantaneous single-tooth meshing characteristics of ......

Industry News

What Motors are Used in an Ice Cream Maker?

We offer a range of AC motors with varying power levels, as well as high-efficiency brushless motors. Our brushless motors are designed for low power ......

Industry News

How to optimize planetary gearboxes to improve the motion performance of industrial robotic arms?

1. High-precision design and manufacturingIndustrial robotic arms have extremely high requirements for motion accuracy, and the accuracy of planetary ......

Industry News

Where can Brushless Motor be Applied?

In conveyor pizza ovens, hot air convection technology ensures rapid heating, minimal heat loss, and uniform cooking. Timing mechanisms are integrated......

Industry News

Excitation method of DC reduction motor

1. Separately excited DC motorThe excitation winding is not connected to the armature winding, and the DC motor powered by other DC power supplies is ......