Product Features

■The Characteristics Of Brushless Motor Suitable For Speed Control Are Introduced

On brushless motor ,it is unecessarily using brush .commutator and any other mechanical contact. Brush motor need brush and commutato to running ,so it need to regular maintain. However, brushless motor used Hall 1C to detect the signal and used driving circuit of crystal catheter's ON/OFF. So it dispense with maintain.

■Stable Speed Control

Brushless DC motors compare the setting speed with the speed feedback signals from the motor at all times and adjust the motor's applied voltageFor this reason, even if the load changes, stable rotation is performed from low speed to high speed.Common inverter-controller three-phase induction motors do not have this type of feedback control and when the load changes, the speed can be affected. Brushless DC motors are recommended for applications that require the speed to be maintained regardless of the load fluctuation.

■Wide Speed Control Range (ZD is Currently the Rate Limiting to 2500RPM, This Drive Change can be Applied to the 4000RPM Motor)

The brushless DC motor has a broader speed control range compared to three-phase inverter driven motors. Unlike three-phase inverter driven motors, the torque at low speed isnot limited, so brushless DC motors are suited for applications that require constant.

|

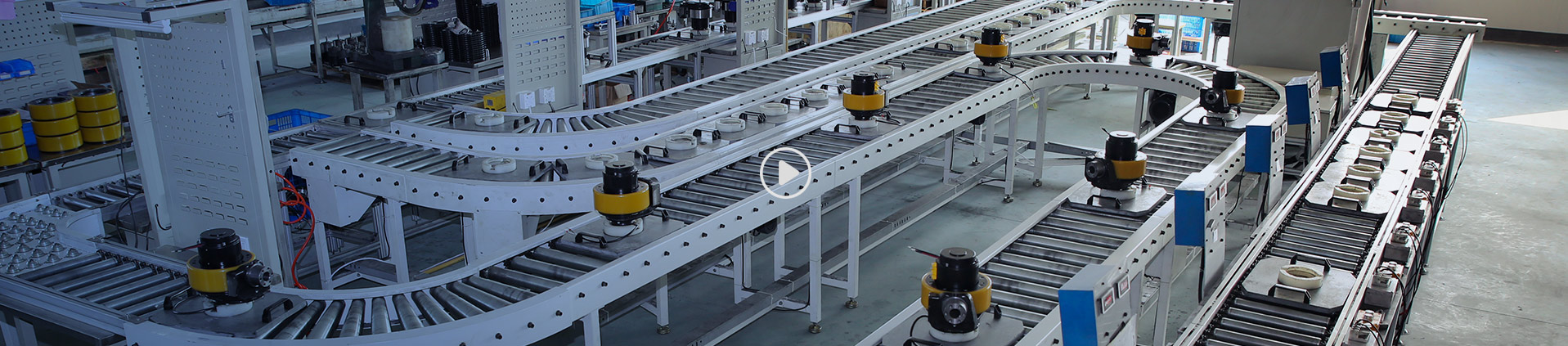

Product Style

|

Speed Control Range

|

Rate Ratio

|

|

Brushless motor

|

80-4000

|

50

|

|

Frequency converter control

Three phase induction motor

|

200-2400

|

12

|

|

AC speed regulating motor

|

50Hz: 90-1400

|

15

|

|

60Hz: 90-1600

|

17

|

■Saving Energy

DC Brushless motor used permanent magnets, it can reduce the secondary loss of rotor. So compared with adopts frequency conversion control of three-phase induction motor, the power reduced 23%. This is in favour of saving energy.

■Low Speed And High Torque Performance

DC brushless motor have a steady big torque when running at low speed.

|

•Z5BLD120-220GU-25S Diagram (ZD Standard Drive)

|

•5IK120RGU-CF (220V/50Hz)( ZD Standard Drive)

|

•Working performance table of brushless motor and ac speed adjustable motor

|

Serial

Number

|

Z5BLD120-220GU-25S

|

5IK120RGU-CF

|

|

Moment

N.m

|

Speed

rpm

|

Current

A

|

Efficiency

%

|

Temperature Rise

K

|

Moment

N.m

|

Speed

rpm

|

Current

A

|

Efficiency

%

|

Temperature Rise

K

|

|

1

|

0.595

|

200

|

0.485

|

26.5

|

≤50K

|

0.010

|

200

|

0.850

|

3.00

|

<80K

|

|

2

|

0.595

|

500

|

0.671

|

47.5

|

≤50K

|

0.150

|

500

|

1.070

|

8.00

|

<80K

|

|

3

|

0.595

|

1000

|

0.966

|

62.0

|

≤40K

|

0.500

|

1000

|

1.186

|

32.5

|

<80K

|

|

4

|

0.595

|

1500

|

1.200

|

69.0

|

≤40K

|

0.915

|

1400

|

0.981

|

60.0

|

<55K

|

|

Ambient temperature10℃~+40℃ environment

|

■Thin, High Power

Brushless DC motors have a slim body and provide high power due to permanent magnets being used in the rotor. For example, the overall length is 75mm shorter and the output power is 1.3 times higher than that of three-phase induction motors with a frame size of 90mm. Using brushless DC motors can contribute to downsizing and space saving.

■Protection Function, Help To Protect The Safety Of The Equipment System

Due to the load of the overcurrent, undervoltage, open phase protection, for this reason can ensure the safety of equipment system.

■Motor Spec Speed

|

Motor Speed\Output Shaft Speed\Reduction

Ratio

|

3

|

3.6

|

5

|

6

|

7.5

|

9

|

10

|

12.5

|

15

|

18

|

20

|

25

|

|

200-1500RPM

|

67~500

|

56~417

|

40~300

|

33~250

|

27~200

|

22~167

|

20~150

|

16~120

|

13~100

|

11~83

|

10~75

|

8~60

|

|

2000RPM

|

667

|

556

|

400

|

334

|

267

|

223

|

200

|

160

|

134

|

112

|

100

|

80

|

|

2500RPM

|

833

|

695

|

500

|

417

|

334

|

278

|

250

|

200

|

167

|

139

|

125

|

100

|

|

Motor Speed\Output Shaft Speed\Reduction

Ratio

|

30

|

36

|

50

|

60

|

75

|

90

|

100

|

120

|

150

|

180

|

200

|

|

200-1500RPM

|

7~50

|

6~42

|

4~30

|

3~25

|

3~20

|

2~17

|

2~15

|

2~12.5

|

1.5~10

|

1~8

|

1~7.5

|

|

2000RPM

|

67

|

56

|

40

|

34

|

27

|

23

|

20

|

17

|

14

|

12

|

10

|

|

2500RPM

|

84

|

70

|

50

|

42

|

34

|

28

|

25

|

21

|

17

|

14

|

12.5

|

■Motor Spec Product Type

|

Motor

|

Square Size

|

Output Power

|

Model

|

Driver

|

Voltage Supply

|

|

60X60

|

15、25

|

Standard type

IP40

Or IP54

|

|

DC24-48

Single phase 100-120V

Single phase 220〜240V

|

|

80X80

|

40、60

|

|

90X90(GN)

|

40、60

|

|

90X90(GU)

|

60、 90、 120

|

|

104X104

|

200、 400

|

■Motor Spec-Basic Performance

|

Project Iteam

|

Motor

|

Driver

|

|

Insulation resistance

(No motor and drive connection state test)

|

50MΩ or more when 500VDC megger is applied between the windings and the case after continuous operation under normal ambient temperature and humidity

|

50MΩ or more when 500VDC megger is applied between the power supply terminal and the protective earth terminal, and between the power supply terminal and the I/O signal terminal after continuous operation under normal ambient temperature and humidity

|

|

Insulation resistance

(No motor and drive connection state test)

|

Sufficient to withstand 1.5kv AC at 50Hz applied between the windings and the case for 1 minute after continuous operation under normal ambient temperature and humidity

|

Sufficient to withstand 1.5kvAC at 50Hz applied between the power supply terminal and the protective earth terminal and the I/O signal terminal for 1 minute after continuous operation under normal ambient temperature and humidity

|

|

Temperature rise

|

The temperature rise of windings is 55℃ max, and that of the case surface is 40℃ max, measured by the thermocouple method after rated continuous operation under normal ambient temperature and humidity①

|

The temperature of the heat sink is 50℃ max, measured by the thermocouple method after rated continuous operation under normal ambient temperature and humidity

|

|

Use environment

|

Ambient temperature

|

-10℃~+40℃ (Non-freezing)

|

|

Ambient humidity

|

85% or less (No-condensing)

|

|

Altitude

|

1000m following

|

|

Medium environment

|

Non corrosive gas, dust; can not be used in a special environment containing radioactive substances, magnetic fields and vacuum, etc

|

|

Vibration

|

Not to exert a continuous vibration or excessive impact

|

|

Storage environment ②

|

Ambient temperature

|

-10℃ ~+40℃ (Non-freezing)

|

|

Ambient humidity

|

85% or less (No-condensing)

|

|

Altitude

|

1000m following

|

|

Heat resistance grade

|

B stage

|

/

|

|

Protection level

|

IP40 & IP54

|

IP20

|

① In order to make the motor shell surface temperature can be maintained below 90℃, the motor installed in the following dimensions of the radiating plate (Material: aluminum); thickness of 25W: 115X115X5, the thickness of the 60W: 135X135X5, the thickness of the 120W: 165X165X5, the thickness of the 200W: 200X200X5. (Unit: mm)

② The storage condition applies to a short period such as a period during transportation.

EN

EN