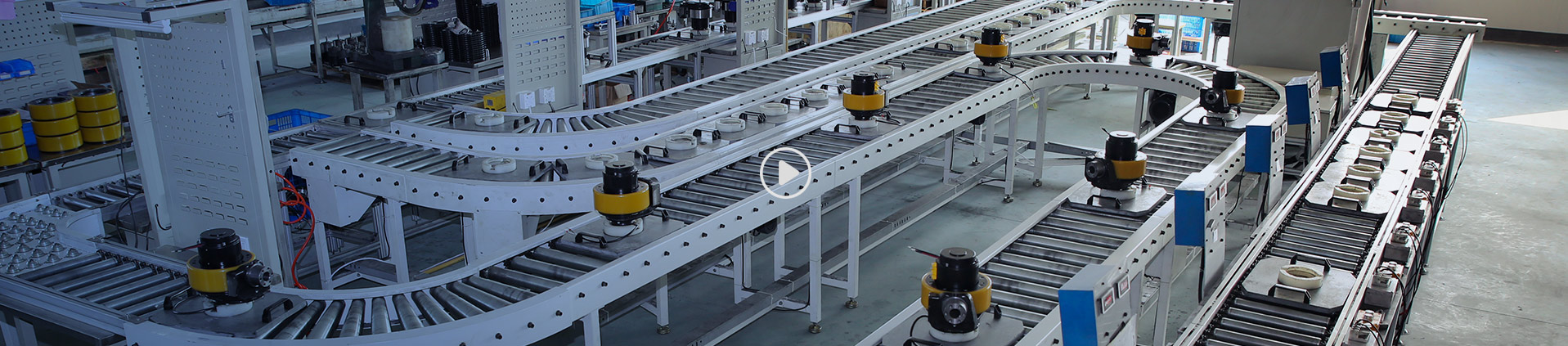

Ningbo Zhongda Leader Intelligent Transmission Co., Ltd is a High-tech public enterprise specializing in research & development, manufacture, sales and service of motor driver, micro motor and high precision gearbox. August 29, 2017, Zhongda went public in the Shenzhen Stock Exchange SME board A-shares (stock code 002896), As a one of the powerful DC Brush Drive Wheel with 210mm Diameter Wheel manufacturers and DC Brush Drive Wheel with 210mm Diameter Wheel suppliers in China. our company Participated in the drafting of 7 National Industrial Standards, Own 90 national patents, Have Zhejiang provincial enterprise R & D Center, our DC Brush Drive Wheel with 210mm Diameter Wheel and other products are widely used in industrial robots, intelligent logistics, new energy, machine tools and other fields, as well as special machinery and equipment for food, packaging, textile, electronics, medical, etc. for their differentiated and cost-effective advantages.

No. of Employees: 1,500 employees

Mission: Zhongda realizes the infinite possibilities in automation applications.

Main Business: It is a High-tech public enterprise specializing in research & development, manufacture, sales and service of motor driver, micro motor and high precision gearbox.

Main Products: Micro DC & AC gear motor, small AC gear motor, planetary gearbox, high precision cycloidal gearbox and motor driver, etc.

Tips: Not all gearbox catalogue listed. Feel free to inquire and get latest catalogue. Need solution? We'd like to help.

EN

EN