■ When Input Speed Is 3,000rpm (120)

|

※1 Type |

Output Shaft Speed |

※2 Rated Output Shaft Torque |

※3 Instantaneous Max.0utput Torque |

X10-4kgm2 Inertia Moment |

||||

|

Type No. |

Model |

Reduction Ratio |

Motor Power |

(rpm) |

(Nm) |

(Nm) |

Flange |

Output Shaft |

|

120 |

ZDG□ |

5 |

1000 |

600 |

12.1 |

36.3 |

2.51 |

2.72 |

|

120 |

ZDG□ |

5 |

1500 |

600 |

20.0 |

60.1 |

2.51 |

2.72 |

|

120 |

ZDG□ |

5 |

2000 |

600 |

28.0 |

84.0 |

2.51 |

2.72 |

|

120 |

ZDG□ |

5 |

2500 |

600 |

35.8 |

107 |

2.51 |

2.72 |

|

120 |

ZDG□ |

5 |

3000 |

600 |

43.0 |

129 |

4.12 |

4.33 |

|

120 |

ZDG□ |

5 |

3500 |

600 |

51.2 |

154 |

4.12 |

4.33 |

|

120 |

ZDG□ |

5 |

4000 |

600 |

58.5 |

176 |

4.12 |

4.33 |

|

120 |

ZDG□ |

5 |

4500 |

600 |

65.9 |

198 |

4.12 |

4.33 |

|

120 |

ZDG□ |

5 |

5000 |

600 |

73.2 |

220 |

4.12 |

4.33 |

|

120 |

ZDG□ |

9 |

750 |

333 |

17.6 |

52.8 |

1.04 |

1.11 |

|

120 |

ZDG□ |

9 |

1000 |

333 |

24.6 |

73.9 |

2.05 |

2.12 |

|

120 |

ZDG□ |

9 |

1500 |

333 |

37.8 |

113 |

2.05 |

2.12 |

|

120 |

ZDG□ |

9 |

2000 |

333 |

51.5 |

155 |

2.05 |

2.12 |

|

120 |

ZDG□ |

9 |

2500 |

333 |

65.9 |

192 |

2.05 |

2.12 |

|

120 |

ZDG□ |

9 |

3000 |

333 |

79.0 |

192 |

3.66 |

3.73 |

|

120 |

ZDG□ |

9 |

3500 |

333 |

92.2 |

192 |

3.66 |

3.73 |

|

120 |

ZDG□ |

11 |

750 |

273 |

19.9 |

59.8 |

1.77 |

1.82 |

|

120 |

ZDG□ |

11 |

1000 |

273 |

28.7 |

86.1 |

2.81 |

2.86 |

|

120 |

ZDG□ |

11 |

1500 |

273 |

45.1 |

135 |

2.81 |

2.86 |

|

120 |

ZDG□ |

11 |

2000 |

273 |

60.5 |

185 |

2.81 |

2.86 |

|

120 |

ZDG□ |

15.4 |

750 |

195 |

30.9 |

92.6 |

1.47 |

1.49 |

|

120 |

ZDG□ |

15.4 |

1000 |

195 |

43.1 |

129 |

2.51 |

2.53 |

|

120 |

ZDG□ |

15.4 |

1500 |

195 |

66.1 |

198 |

2.51 |

2.53 |

|

120 |

ZDG□ |

15.4 |

2000 |

195 |

88.2 |

265 |

2.51 |

2.53 |

|

120 |

ZDG□ |

15.4 |

2500 |

195 |

110 |

285 |

2.51 |

2.53 |

|

120 |

ZDG□ |

21 |

750 |

143 |

42.1 |

126 |

1.43 |

1.45 |

|

120 |

ZDG□ |

21 |

1000 |

143 |

58.8 |

176 |

2.47 |

2.48 |

|

120 |

ZDG□ |

21 |

1500 |

143 |

90.2 |

271 |

2.47 |

2.48 |

|

120 |

ZDG□ |

21 |

2000 |

143 |

120 |

318 |

2.47 |

2.48 |

|

120 |

ZDG□ |

33 |

400 |

91 |

34.4 |

103 |

0.345 |

0.350 |

|

120 |

ZDG□ |

33 |

750 |

91 |

69.3 |

208 |

0.941 |

0.946 |

|

120 |

ZDG□ |

33 |

1000 |

91 |

94.5 |

283 |

1.86 |

1.86 |

|

120 |

ZDG□ |

33 |

1500 |

91 |

138 |

285 |

1.86 |

1.86 |

|

120 |

ZDG□ |

45 |

400 |

67 |

47.0 |

141 |

0.338 |

0.341 |

|

120 |

ZDG□ |

45 |

750 |

67 |

94.5 |

283 |

0.934 |

0.936 |

|

120 |

ZDG□ |

45 |

1000 |

67 |

129 |

318 |

1.85 |

1.85 |

|

120 |

ZDG□ |

81 |

200 |

37 |

42.3 |

127 |

0.235 |

0.236 |

|

120 |

ZDG□ |

81 |

400 |

37 |

88.7 |

191 |

0.235 |

0.236 |

※ The torque limit model. In detail, please contact the sales department.

※ The rated output torque motor rated torque reducer output torque.

※ The instantaneous maximum output torque motor instantaneous maximum torque.

※ When the output torque of reducer. However, the instantaneous maximum torque of the motor is assumed to be 3 times that of the rated torque.

※ The situation of motor instantaneous maximum torque Rated torque is 3 times, please contact in advance with the company.

※ If the reduction ratio of the situation outside the sales office to please.

EN

EN

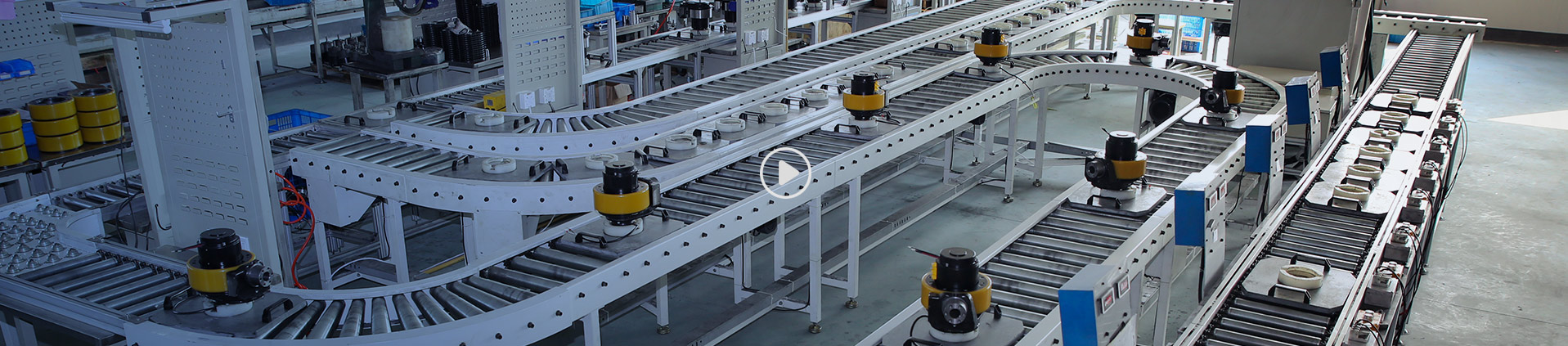

1.Precision machine clip system

1.Precision machine clip system