We can provide customized products and project products according to specific requirements. Please feel free to contact us if you need.

|

Product type |

|

115 |

142 |

190 |

Reduction ratio |

Number of stage |

|

Rated output torque |

N.M |

150 |

400 |

1000 |

3 |

1 |

|

200 |

560 |

1200 |

4 |

|||

|

210 |

700 |

1600 |

5 |

|||

|

148 |

450 |

1000 |

8 |

|||

|

125 |

305 |

630 |

10 |

|||

|

210 |

780 |

1500 |

12 |

2 |

||

|

210 |

780 |

1500 |

15 |

|||

|

260 |

910 |

1800 |

16 |

|||

|

260 |

910 |

1800 |

20 |

|||

|

210 |

780 |

1800 |

25 |

|||

|

260 |

910 |

1800 |

32 |

|||

|

210 |

780 |

1800 |

40 |

|||

|

148 |

450 |

1000 |

64 |

|||

|

125 |

305 |

630 |

100 |

|||

|

Life |

Hour |

20,000 |

|

|||

|

Instant stop torque |

N.M |

Two times of rated output torque |

|

|||

|

Product type |

115 |

142 |

190 |

Unit |

Number of stage |

|

|

Max radial torque |

4300 |

8200 |

12000 |

N |

|

|

|

Max axial torque |

12000 |

19000 |

28000 |

N |

|

|

|

Full load efficiency |

96 |

% |

1 |

|||

|

94 |

2 |

|||||

|

Weight |

9 |

15.4 |

33.5 |

Kg |

1 |

|

|

11.6 |

18.5 |

45 |

2 |

|||

|

Operating temperature |

-25~+90 |

℃ |

|

|||

|

IP |

IP65 |

|

||||

|

Lubrication type |

Lifetime lubrication |

|

||||

|

Mounting type |

Any |

|

||||

The max radial and axial torque work in the location of the center of output shaft when the out speed is 100RPM.

|

Product type |

|

115 |

142 |

190 |

Reduction ratio |

|

Moment of inertia |

kgcm2 |

2.10 |

12.14 |

47.52 |

3 |

|

1.51 |

7.78 |

29.69 |

4 |

||

|

1.22 |

6.07 |

23.18 |

5 |

||

|

1.05 |

4.63 |

16.83 |

8 |

||

|

1.00 |

4.25 |

15.32 |

10 |

||

|

1.48 |

7.47 |

28.95 |

12 |

||

|

1.41 |

6.65 |

22.71 |

15 |

||

|

1.48 |

7.47 |

28.95 |

16 |

||

|

1.41 |

6.65 |

22.71 |

20 |

||

|

1.21 |

5.81 |

22.46 |

25 |

||

|

1.46 |

6.36 |

16.65 |

32 |

||

|

1.05 |

5.28 |

16.54 |

40 |

||

|

1.05 |

4.50 |

16.45 |

64 |

||

|

1.00 |

4.17 |

15.07 |

100 |

|

Product type |

|

115 |

142 |

190 |

Number of stage |

|

Backlash |

arcmin

|

<8 |

<8 |

<8 |

1 |

|

<12 |

<12 |

<12 |

2 |

||

|

Torsional stiffness |

N.M/arcmin |

20 |

44 |

130 |

1 |

|

22 |

46 |

140 |

2 |

||

|

Noise |

dB(A) |

65 |

68 |

70 |

|

|

Max iuput speed |

min-1 |

4500 |

4500 |

3000 |

|

|

Recommnd iuput speed |

min-1 |

3000 |

3000 |

2000 |

|

1.The moment of inertia is related with input shaft.

2.Noise test standard pressure level, distance 1m, measured on idle runninq with an input speed of 3000rpm.

|

Product type |

115ZDS |

142ZDS |

190ZDS |

|||

|

Number of stage |

1 |

2 |

1 |

2 |

1 |

2 |

|

L1 overall length |

213 |

246.5 |

289 |

338.5 |

308.5 |

356 |

|

L3 body length |

77.5 |

111 |

102 |

151.5 |

121.5 |

169 |

|

Output |

||||||

|

L4 output shaft length |

64.5 |

87 |

90 |

|||

|

L5 output length to the shaft shoulder |

58 |

80 |

82 |

|||

|

L6 key length |

50 |

70 |

70 |

|||

|

L7 key length to the shaft end |

4 |

5 |

6 |

|||

|

L8 spigot length |

4 |

5 |

6 |

|||

|

L11 output flange thickness |

14 |

20 |

20 |

|||

|

D4 output shaft diameter |

Φ32h7 |

Φ40h7 |

Φ55h7 |

|||

|

D5 shaft shoulder diameter |

Φ55 |

Φ65 |

Φ95 |

|||

|

D6 spigot diameter |

Φ110h7 |

Φ130h7 |

Φ160h7 |

|||

|

D7 body diameter |

□115 |

□142 |

□190 |

|||

|

D8 flange hole circle |

Φ130 |

Φ165 |

Φ215 |

|||

|

D9 mounting bore |

Φ8.5 |

Φ11 |

Φ13.5 |

|||

|

B1 key width |

10 |

12 |

16 |

|||

|

H1 key height |

35 |

43 |

59 |

|||

|

G3 center screw hole |

M12X25 |

M12X25 |

M16X35 |

|||

|

L13 recess width |

34 |

67.5 |

52 |

101.5 |

52 |

99.5 |

|

L14 recess |

□115 |

□142 |

□190 |

|||

|

Input |

||||||

|

L2 input flange length |

71 |

100 |

105 |

|||

|

L9 motor shaft length |

58 |

79 |

82 |

|||

|

L10 spigot depth |

10 |

10 |

8 |

|||

|

D1 mounting hole distribution circle |

Φ145 |

Φ200 |

Φ215 |

|||

|

D2 spigot diameter |

Φ110G7 |

Φ114.3G7 |

Φ180G7 |

|||

|

D3 input shaft diameter |

≤Φ24G7 |

≤Φ35G7 |

≤Φ42G7 |

|||

|

G1 mounting threads x depth |

M8X22 |

M12X25 |

M12X25 |

|||

|

Q3 iutput flange |

□130 |

□175 |

□190 |

|||

Input size made according to motor size.

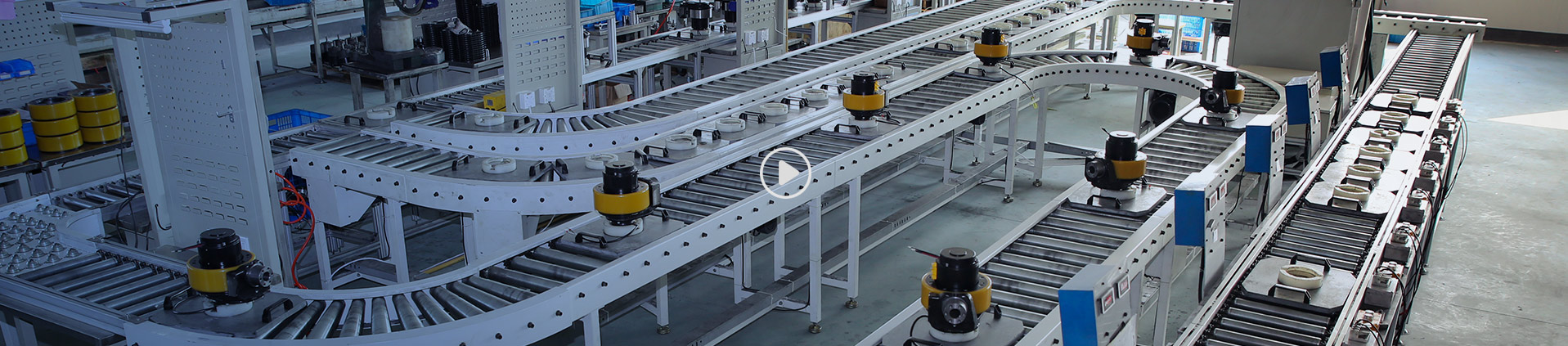

Ningbo Zhongda Leader Intelligent Transmission Co., Ltd is a High-tech public enterprise specializing in research & development, manufacture, sales and service of motor driver, micro motor and high precision gearbox. August 29, 2017, Zhongda went public in the Shenzhen Stock Exchange SME board A-shares (stock code 002896), As a one of the powerful ZDS Series Precision Spur Planetary Gearbox manufacturers and ZDS Series Precision Spur Planetary Gearbox suppliers in China. our company Participated in the drafting of 7 National Industrial Standards, Own 90 national patents, Have Zhejiang provincial enterprise R & D Center, our ZDS Series Precision Spur Planetary Gearbox and other products are widely used in industrial robots, intelligent logistics, new energy, machine tools and other fields, as well as special machinery and equipment for food, packaging, textile, electronics, medical, etc. for their differentiated and cost-effective advantages.

No. of Employees: 1,500 employees

Mission: Zhongda realizes the infinite possibilities in automation applications.

Main Business: It is a High-tech public enterprise specializing in research & development, manufacture, sales and service of motor driver, micro motor and high precision gearbox.

Main Products: Micro DC & AC gear motor, small AC gear motor, planetary gearbox, high precision cycloidal gearbox and motor driver, etc.

Tips: Not all gearbox catalogue listed. Feel free to inquire and get latest catalogue. Need solution? We'd like to help.

Show Information

News & Media

Industry News

What are the advantages of planetary gear motors in the field of robotics?

1. Efficient and compact design, breaking through space limitationsThe planetary gear motor adopts a unique planetary gear train structure (sun gear, ......

Industry News

Why are planetary gearboxes widely used in high-precision equipment?

I. Technical Features: Core Engineering ExcellenceUltra-Low Backlash & High Positioning AccuracyPlanetary gearboxes utilize precision meshing desi......

Industry News

How to Determine if a Gear Motor Needs Replacement?

1. Mechanical Wear and Structural IntegrityThe first step is to inspect the mechanical components for irreversible wear or damage. Gears should be exa......

Industry News

What are the advantages of using gear motors in the field of automation?

1. High torque output and power adaptabilityGear motors convert the high-speed and low-torque output of motors into low-speed and high-torque through ......

Industry News

What are the Applications of AC Gear Motor in the Commercial Ice-making Equipment?

Commercial ice-making equipment is a machine used for large-scale production of ice cubes or ice particles, widely used in the catering, medical, and ......

Industry News

What Are the Gears Used in a Planetary Gearbox?

1. Sun GearLocated at the center of the assembly, the sun gear is driven by the input shaft and transmits rotational force to the planetary gears .Typ......